Our References

Showcasing our successful collaborations and project highlights.

Instant Safety: Forklift & Pedestrian Collision Avoidance System

Client: Major Hungarian Warehouse Automation Integrator | End User: Consumer Goods Manufacturer | Year: 2025

Challenge: To eliminate the risk of collisions at busy junctions where personnel on foot frequently cross forklift traffic paths within a dynamic warehouse environment.

Solution: We deployed a UWB-based safety system, equipping forklifts and pedestrian crossing gates with UWB radios. When a person opens a gate to cross, a signal is instantly sent to all forklifts within a 10-meter radius, automatically slowing them to a safe speed.

Automatic Volume Measurement for Wood Trucks

Client: Wood Panel Manufacturer | Year: 2024

Challenge: A production expansion led to increased truck traffic at the factory gate. The existing manual measurement process for incoming wood shipments was time-consuming and prone to documentation errors, creating a significant bottleneck.

Solution: Famidat developed an automatic volume measurement solution using stereo depth camera technology. The system creates a precise 3D model of the wood on the truck, calculating the volume in under one minute while the truck is stopped at the weight scale, drastically improving speed and accuracy.

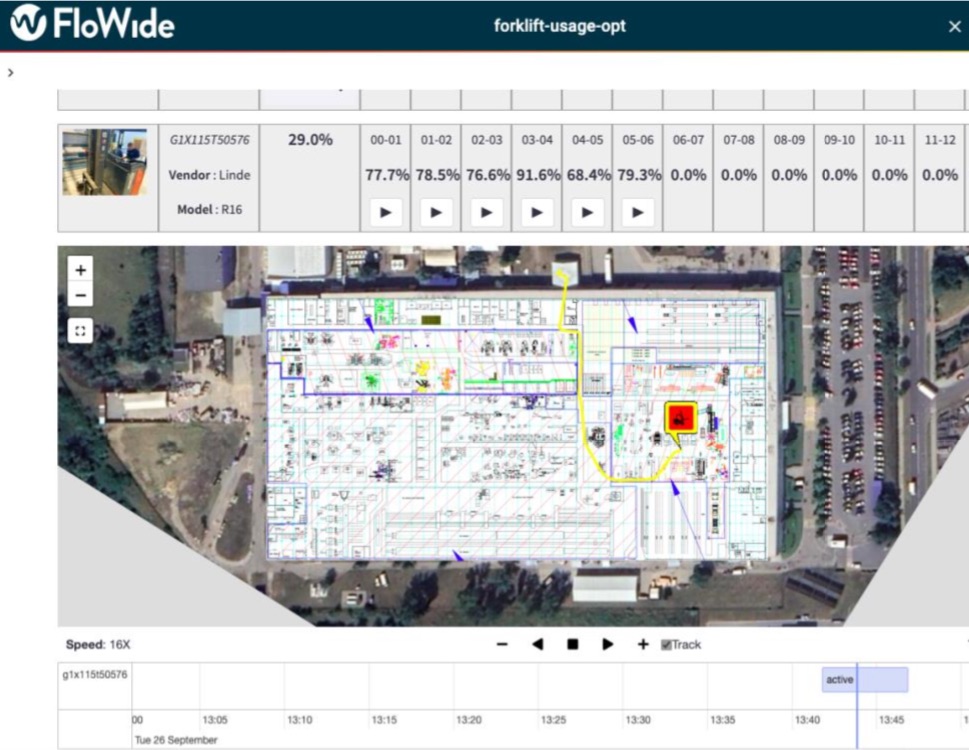

Hybrid RTLS and Unified Reporting for a Heterogeneous Fleet

Client: Abrasives Manufacturer, Poland | Year: 2023

Challenge: Supervising a heterogeneous fleet of more than 70 forklifts, where some already had vendor-implemented fleet tracking, but 23 devices provided no data. The goal was to create a unified, comprehensive utilization report for the entire fleet.

Solution: We deployed a hybrid RTLS on the 33,000m² shopfloor, using UWB tracking in areas where precision was required and BLE tracking where presence reporting was sufficient. We also created a reporting application that unifies data from the 3rd party fleet tracking and our RTLS to provide a single, unified forklift utilization report.

Where is my sewing machine? - Indoor Tracking for an Automotive Supplier

Client: Mulitnational Tier-1 Automotive in Hungary | Year: 2022

Challenge: Needed a highly accurate real-time location system (RTLS) to track more than 130 sewingmachines on wheels across a 7,000 sq meter production area to improve maintenance and operational efficiency.

Solution: Deployed FloWide's end-to-end RTLS solution, including custom hardware integration and a tailored software including a livemap showing each sewmachine real-time status and position. The system provided sub-meter accuracy and seamless integration with the client's existing connected workforce software.

Need to stop that Forklift! - Custom Hardware Development

Client: Hungarian Startup | Year: 2021

Challenge: A startup that developed vision-based forklift traffic control sought a solution to alert nearby forklifts of potential collisions in real time.

Solution: We designed and produced two bespoke radio modules: one universal module for any forklift and another designed to integrate seamlessly with the client's existing hardware system.

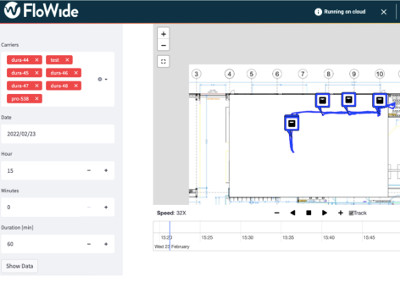

Warehouse Asset Tracking Pilot

Client: Leading Hungarian E-Commerce Partner | Year: 2021

Challenge: The client needed to validate TDOA-based RTLS technology in a complex 5,000m² warehouse, half of which contained high-shelf areas. The goal was to accurately track 8 forklifts and 30 hand pallet trucks to analyze movement and identify inefficiencies before a full-scale rollout.

Solution: Famidat installed a complete FloWide RTLS system in TDOA mode across the pilot area. We tagged all 38 assets and provided a live dashboard for real-time visualization, heatmaps, and path analysis.

Can we track our production in real time? - Indoor Tracking pilot in the Energy Industry

Client: Fortune 500 company from the Energy Industry in Germany | Year: 2022

Challenge: To set up a tracking system in a new production area for a new product line involving the multi-month assembly of high-value electromechanical devices for the renewable energy sector. The goal was to provide a tool for engineers to effectively ramp up the human-workforce-intensive assembly process.

Solution: FloWide RTLS tags were successfully installed and validated to track critical assets. This included tracking storage boxes with valuable components, essential assembly tools, and personnel to understand and optimize workflows.

More detailed case studies and client testimonials are available upon request. Please contact us for more information.